Coastal PVA Company Profile

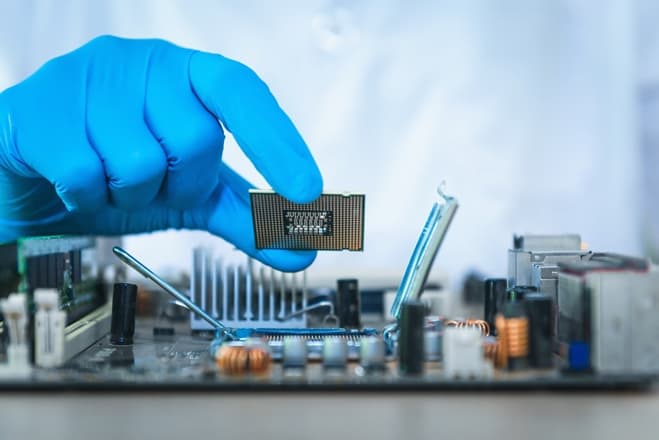

1. Coastal PVA, incorporated in 2006, is a technology driven manufacturer dedicated to supporting and expanding our global customer base through world-class quality and extended brush life rollers

2. Coastal PVA is an ISO 9001 : 2008 Certified Facility

3. We have over 60 years’ combined product design, R&D, and manufacturing experience

4. Coastal PVA has been a key developer and holder of patent-pending technology including Dual-Pore formulations, Thermal-Bonded-On-The Core and FR3 Ultraclean Washing System

5. Manufacturing facilities are located in the Sacramento, CA, USA area and in Costa Rica

6. Our PVA roller brushes are distributed to many areas of the world : Singapore, Malaysia, Taiwan, Japan and USA

7. We continue to expand our business worldwide through distribution partners

2. Coastal PVA is an ISO 9001 : 2008 Certified Facility

3. We have over 60 years’ combined product design, R&D, and manufacturing experience

4. Coastal PVA has been a key developer and holder of patent-pending technology including Dual-Pore formulations, Thermal-Bonded-On-The Core and FR3 Ultraclean Washing System

5. Manufacturing facilities are located in the Sacramento, CA, USA area and in Costa Rica

6. Our PVA roller brushes are distributed to many areas of the world : Singapore, Malaysia, Taiwan, Japan and USA

7. We continue to expand our business worldwide through distribution partners

Our Advantage

Dual Pore

Formulations

化學機械研磨環

CMP是半導體流程最關鍵階段,需精確極小的公差範圍及高品質表面平整度。為了CMP應用需要VICTREX PEEK成為市場最適當的材料之一

- 高尺寸穩定性

- 易於加工

- 良好的機械特性

Thermal Bonded

Core

化學機械研磨環

CMP是半導體流程最關鍵階段,需精確極小的公差範圍及高品質表面平整度。為了CMP應用需要VICTREX PEEK成為市場最適當的材料之一

- 高尺寸穩定性

- 易於加工

- 良好的機械特性

FR3 Ultraclean

Washing System

化學機械研磨環

CMP是半導體流程最關鍵階段,需精確極小的公差範圍及高品質表面平整度。為了CMP應用需要VICTREX PEEK成為市場最適當的材料之一

- 高尺寸穩定性

- 易於加工

- 良好的機械特性

Coastal PVA Manufacturing Process Flow Chart

PVA / Water Solution

Catalyst (Formaldehyde And Acid)

Cleaning (NH4OH Treating)

Final Washing (Ultraclean)

Add Forming Agent

Molding and Reaction

Cutting

Packing

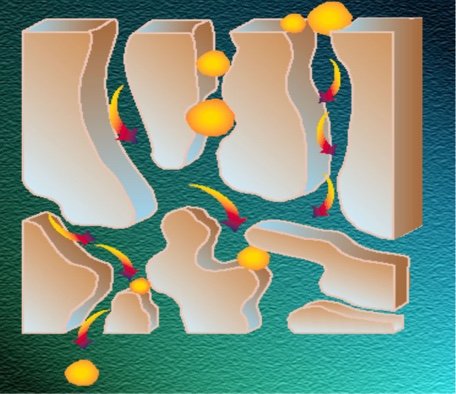

Dual Pore Technology

1. Our patented Dual Pore PVA technology delivers a brush with a pore system designed to optimize flush and deliver optimal flow to your post-CMP cleaning process

2. The Coastal PVA Dual Pore Brush provides water an expanded path via larger pores from the core while maintaining smaller pores at the surface to ensure efficient particulate elimination

3. Coastal PVA’s Dual Pore Brush is engineered to deliver superior performance and wafer to wafer consistency in post-CMP wafer cleaning applications

2. The Coastal PVA Dual Pore Brush provides water an expanded path via larger pores from the core while maintaining smaller pores at the surface to ensure efficient particulate elimination

3. Coastal PVA’s Dual Pore Brush is engineered to deliver superior performance and wafer to wafer consistency in post-CMP wafer cleaning applications

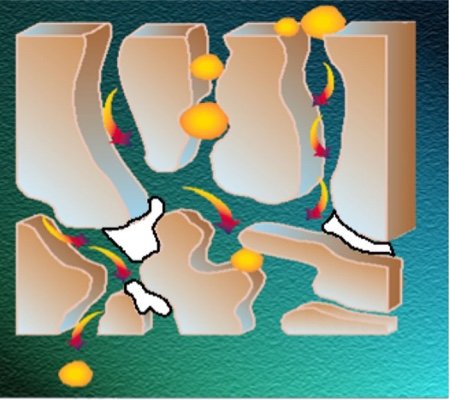

Thermal Bonded Core Technology

Unlike mounted or molded core technologies

1. Coastal PVA’s patented Bonded on Core technology bonds the brush to the core thermally without any adhesives

2. The technology allows the built-in core of our PVA brushes to dynamically adjust to the brushes revolutions on your post-CMP cleaning machines eliminating friction between our PVA brushes and their core

3. Unlike standalone, Friction fitted or molded to the core products, our thermally bonded to the core brush eliminates twisting and crawling of the PVA brush and allows you process flexibility in your tool set up to improve productivity and yields

4. In addition, PVA slippage and expansion is no longer an issue with the use of our Bonded On Core PVA Brushes

5. The Bonded on Core technology provides lifetime stability and consistent performance and dose not require manual mounting to the core eliminating occurrences of operator error

1. Coastal PVA’s patented Bonded on Core technology bonds the brush to the core thermally without any adhesives

2. The technology allows the built-in core of our PVA brushes to dynamically adjust to the brushes revolutions on your post-CMP cleaning machines eliminating friction between our PVA brushes and their core

3. Unlike standalone, Friction fitted or molded to the core products, our thermally bonded to the core brush eliminates twisting and crawling of the PVA brush and allows you process flexibility in your tool set up to improve productivity and yields

4. In addition, PVA slippage and expansion is no longer an issue with the use of our Bonded On Core PVA Brushes

5. The Bonded on Core technology provides lifetime stability and consistent performance and dose not require manual mounting to the core eliminating occurrences of operator error

Coastal PVA

A Leader in Technology, Innovation & Quality

- Dual Pore PVA Brush Formulation

- Optimizes Flush & Improves Particulate Elimination

- Thermally Bonded on Core PVA Brush

- Dynamically Adjusts to Brush Revolutions & Eliminates Twisting

- Manufacturer Direct Pricing

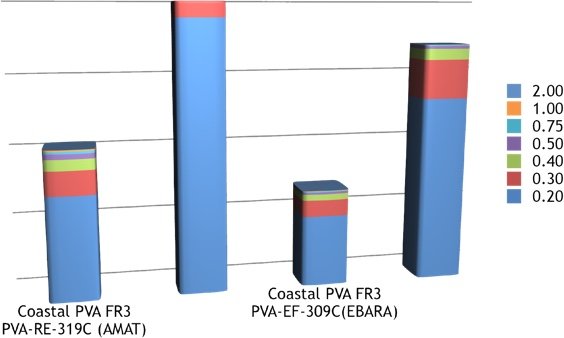

PVA LPC Analysis

向右可瀏覽完整資訊 →

| SIZE (micron) | Coastal PVA FR3 PVA-RE-319C (AMAT) | Entegris PVS1ARXR-1 | Coastal PVA FR3 PVA-EF-309C(EBARA) | Aion BUX102-2 |

|---|---|---|---|---|

| 0.2 | 2200.2 | 5675.7 | 1513.9 | 3953.6 |

| 0.3 | 511.1 | 903.1 | 350.8 | 831 |

| 0.4 | 228.3 | 340.5 | 129.5 | 227.1 |

| 0.5 | 106.7 | 210.8 | 45.6 | 63.5 |

| 0.75 | 47.4 | 42.7 | 17.3 | 17.7 |

| 1 | 32.5 | 35.9 | 10.9 | 10.3 |

| 2 | 3.1 | 4.4 | 1.1 | 1.5 |

| Total | 3129.3 | 7213.1 | 2069.1 | 5104.7 |

Trace Metal Data

向右可瀏覽完整資訊 →

| Parameter | Parameter Chinese Name | Units | Aion (For EBARA) | RIPPEY (For EBARA) | Coastal PVA PVA-EB-309C (For EBARA | Entegris (For AMAT) | Coastal PVA PVA-RE-319C (For AMAT) |

|---|---|---|---|---|---|---|---|

| Aluminum (Al) | 鋁 | ppb(ug/L) | 0.4460 | 0.4460 | 0.4460 | 0.4460 | 0.4460 |

| Barium (Ba) | 鋇 | ppb(ug/L) | 0.7190 | 0.7190 | 0.7190 | 0.7190 | 0.7190 |

| Calcium (Ca) | 鈣 | ppb(ug/L) | 0.0168 | 0.0168 | 0.0168 | 0.0168 | 0.0168 |

| Chromium (Cr) | 鋁 | ppb(ug/L) | 0.4460 | 0.4460 | 0.4460 | 0.4460 | 0.4460 |

| Copper (Cu) | 鋇 | ppb(ug/L) | 0.7190 | 0.7190 | 0.7190 | 0.7190 | 0.7190 |

| Iron (Fe) | 鈣 | ppb(ug/L) | 0.0168 | 0.0168 | 0.0168 | 0.0168 | 0.0168 |

| Lithium (Li) | 鋇 | ppb(ug/L) | 0.7190 | 0.7190 | 0.7190 | 0.7190 | 0.7190 |

| Potassium (K) | 鋁 | ppb(ug/L) | 0.4460 | 0.4460 | 0.4460 | 0.4460 | 0.4460 |

| Magnesium (Mg) | 鈣 | ppb(ug/L) | 0.0168 | 0.0168 | 0.0168 | 0.0168 | 0.0168 |

| Manganese (Mn) | 鋁 | ppb(ug/L) | 0.4460 | 0.4460 | 0.4460 | 0.4460 | 0.4460 |

| Sodium (Na) | 鋇 | ppb(ug/L) | 0.7190 | 0.7190 | 0.7190 | 0.7190 | 0.7190 |

| Lead (Pb) | 鈣 | ppb(ug/L) | 0.0168 | 0.0168 | 0.0168 | 0.0168 | 0.0168 |

| Strontium (Sr) | 鋁 | ppb(ug/L) | 0.4460 | 0.4460 | 0.4460 | 0.4460 | 0.4460 |

| Titanium (Ti) | 鋇 | ppb(ug/L) | 0.7190 | 0.7190 | 0.7190 | 0.7190 | 0.7190 |

| Zinc (Zn) | 鈣 | ppb(ug/L) | 0.0168 | 0.0168 | 0.0168 | 0.0168 | 0.0168 |

| Titanium (Ti) | 鋇 | ppb(ug/L) | 0.7190 | 0.7190 | 0.7190 | 0.7190 | 0.7190 |

IC Date

向右可瀏覽完整資訊 →

| Parameter | Parameter Chinese Name | Units | Aion (For EBARA) | RIPPEY (For EBARA) | Coastal PVA PVA-EB-309C (For EBARA | Entegris (For AMAT) | Coastal PVA PVA-RE-319C (For AMAT) |

|---|---|---|---|---|---|---|---|

| lithium (Li+) | 鋰離子 | ppb(ug/L) | N.D. | N.D. | N.D. | N.D. | N.D. |

| Sodium (Na+) | 鈉離子 | ppb(ug/L) | N.D. | N.D. | N.D. | 46.6 | N.D. |

| Potassium (K+) | 鉀離子 | ppb(ug/L) | 0.0168 | 0.0168 | 0.0168 | 0.0168 | 0.0168 |

| Calcium (Ca2+) | 鈣離子 | ppb(ug/L) | 0.4460 | 0.4460 | 0.4460 | 0.4460 | 0.4460 |

| Magnesium (Mg2+) | 鎂離子 | ppb(ug/L) | 0.7190 | 0.7190 | 0.7190 | 0.7190 | 0.7190 |

向右可瀏覽完整資訊 →

| Parameter | Parameter Chinese Name | Units | Aion (For EBARA) | RIPPEY (For EBARA) | Coastal PVA PVA-EB-309C (For EBARA) | Entegris (For AMAT) | Coastal PVA PVA-RE-319C (For AMAT) |

|---|---|---|---|---|---|---|---|

| Chloride (Cl-) | 氯離子 | ppb(ug/L) | 9.45 | N.D. | 7.39 | N.D. | 10.015 |

| Nitrite (NO2-) | 亞硝酸根離子 | ppb(ug/L) | N.D. | N.D. | N.D. | N.D. | N.D. |

| Bromide (Br-) | 溴離子 | ppb(ug/L) | N.D. | N.D. | N.D. | N.D. | N.D. |

| Nitrate (NO3-) | 硝酸根離子 | ppb(ug/L) | N.D. | N.D. | N.D. | N.D. | N.D. |

| Phosphate (PO43-) | 磷酸根離子 | ppb(ug/L) | N.D. | N.D. | N.D. | N.D. | N.D. |

| Sulfate (SO42-) | 硫酸根離子 | ppb(ug/L) | 6.65 | 1370 | 3.12 | 123 | 6.912 |

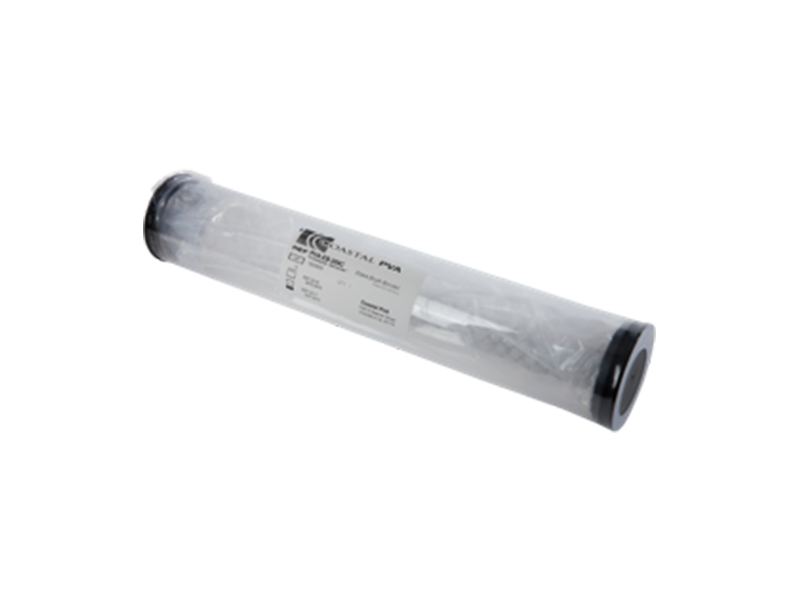

Certification of Customer

tsmc P/N

AMAT:30153482

( for .13um, 90nm, 80nm and 20nm Cu CMP) EBARA:30153460 (for 65nm, 60nm, 45nm and 40nm STI and Cu CMP)

AMAT:30153482

( for .13um, 90nm, 80nm and 20nm Cu CMP) EBARA:30153460 (for 65nm, 60nm, 45nm and 40nm STI and Cu CMP)

UMC P/N

AMAT:S00116337K (for 28nm Cu CMP)

Global Foundries (Singapore)

AMAT:(for 90nm, 65nm, 60nm, 45nm and 40nm Cu CMP)

AMAT:S00116337K (for 28nm Cu CMP)

Global Foundries (Singapore)

AMAT:(for 90nm, 65nm, 60nm, 45nm and 40nm Cu CMP)

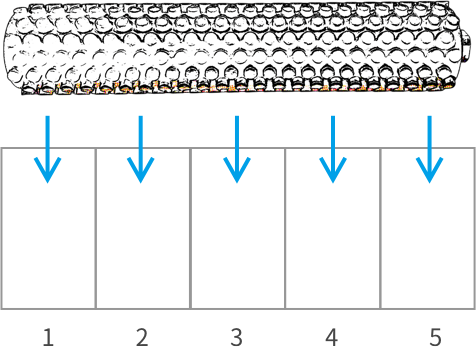

tsmc Request Test Data

向右可瀏覽完整資訊 →

| Manufacturer | Compression (gm/cm2) | % of Compression Difference | Aion (For EBARA) | RIPPEY (For EBARA) |

|---|---|---|---|---|

| Coastal | 138.37 | Baseline | 0.198 | Baseline |

| Entegris | 140.6 | 1.61% | 0.204 | 2.86% |

| Aion | 117.16 | -15.33% | 0.193 | -2.53% |

| Rippy "soft" | 98.47 | -28.84% | 0.194 | 2.02% |

向右可瀏覽完整資訊 →

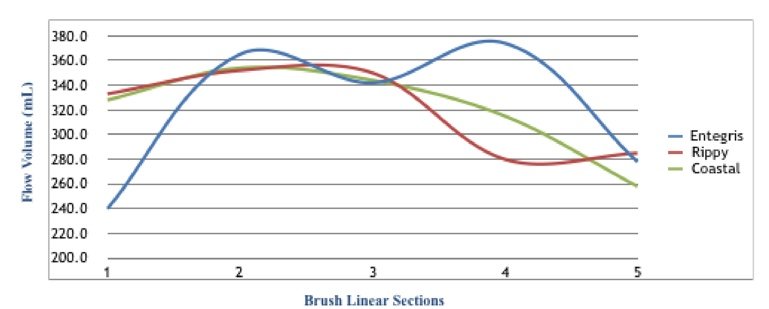

| Manufacturer | section1 | section2 | section3 | section4 | section5 | Total Volume (mL) |

|---|---|---|---|---|---|---|

| Entegris | 15% | 22.8% | 21.4% | 23.4% | 17.4% | 1563 |

| Rippy "soft" | 20.8% | 22% | 21.9% | 17.5% | 17.8% | 1489 |

| Coastal | 20.5% | 22.1% | 21.5% | 19.7% | 16.1% | 1535 |

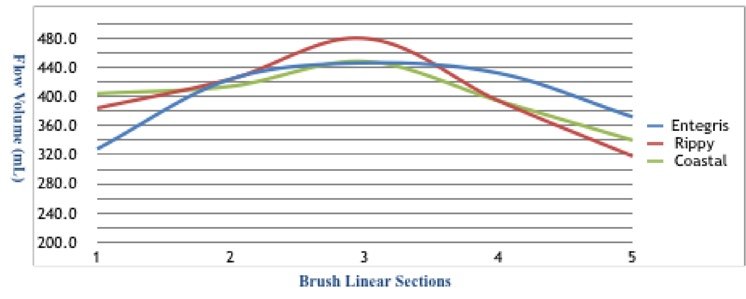

向右可瀏覽完整資訊 →

| Manufacturer | section1 | section2 | section3 | section4 | section5 | Total Volume (mL) |

|---|---|---|---|---|---|---|

| Entegris | 16.4% | 21.2% | 22.3% | 21.6% | 18.6% | 1993 |

| Rippy "soft" | 19.2% | 21.2% | 24% | 19.7% | 15.9% | 1996 |

| Coastal | 20.2% | 20.7% | 22.4% | 19.7% | 170% | 1966 |

Coastal PVA Brush